Visibility: Clear

Current: Strong

Report: Great news! We’re starting to get sample parts from our injection molding vendor. This is a huge step forward for NEMO and we could not be more excited. However, there’s a significant amount of testing to be done before we can call the molds a success. We’ve also gotten started on laying out the production line. The rest of the line is going to come together very quickly as we finalize the remaining processes and quality tests.

Injection Molding:

This has been a memorable week for NEMO! The first injection molded part samples arrived at headquarters for testing – what an amazing feeling it is to hold these parts in our hands. We haven’t received samples for each part yet, but so far everything is coming out great. The first revision of sample parts, called T0, are used to confirm the main design of the mold and the functionality of the parts. Once the parts are confirmed by the BLU3 engineers, the molds will be adjusted for any necessary changes and then surface textures will be added to give the parts their desired cosmetic appearance.

The first parts that we received are the Smart Reg™ silicone purge button and diaphragm as well as the flexible pump end caps. There are some minor changes to make on each part, but for the most part we’re very happy with how they’ve come out!

End Caps, Smart Reg™ Purge Button, Smart Reg™ Diaphragm

On the silicone parts, the only changes needed are to color match the blue color with the color on the air hose. On the end caps, we are going to try a softer durometer since these samples came a little more stiff than desired. We have three different durometer samples on the way so that we can narrow in on it as quickly as possible. There’s still more testing to do with the end caps to ensure the design is correct, but we did get a chance to hop in the pool for a quick test dive and things went very smoothly.

Pool Testing the End Caps, Smart Reg™ Purge Button and Smart Reg™ Diaphragm

Later in the week, we received more sample parts. Only brief inspections have been performed so far and there’s a bit of testing to be completed before confirming these parts. However, we’re very impressed – and excited!

More T0 Parts

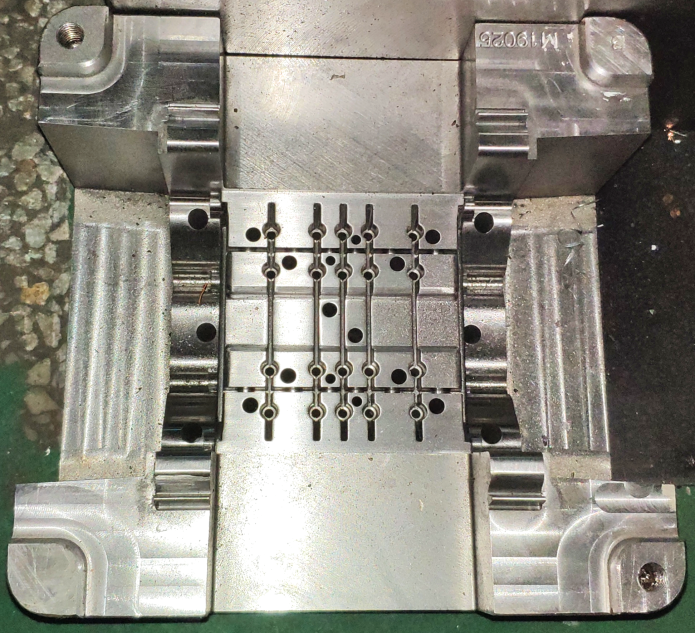

We will be seeing samples from other parts over the next two weeks as the first revision of the other molds are completed. Here’s a few photos of the mold for the pump body, our most complex part. We should be receiving samples from this mold sometime next week. We can’t wait to build the first entirely injection molded NEMO.

Pump Body Mold Work in Progress

Assembly Line:

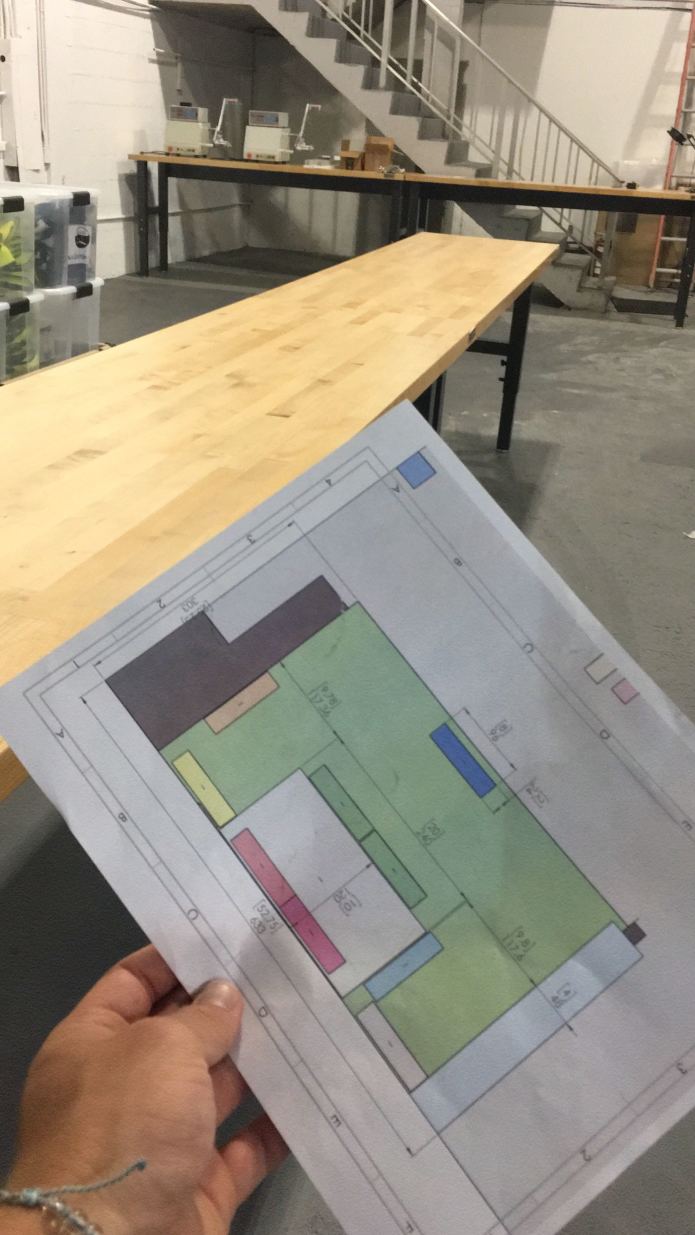

This week we cleared the warehouse out so we could paint the wall white before our work benches arrived. This will help with lighting and give the room a comfortable feel to it. Our work benches all arrived late in the week and they’ve been laid out according to plan. We already see some adjustments that we may want to make to the layout, but for the most part it looks like our plan is going to come together very nicely! Soon these tables will be filled with fixtures and machines used for assembly. We’ve also got storage racks on the way for holding our parts inventory.

Production Line Setup Underway

Forecast: Things really are coming together! There are some parts we’re still waiting to receive, the most significant being the battery packs and the foam flotation units. We expect that first NEMO’s will not make it out this month and will most likely be delivered in June. You can be sure that the team is working extremely hard to deliver your NEMO to you as quickly as possible. We’re all dreaming of the production line running like a well-oiled machine. Thank you again to our backers for your support!

BLU3 Team